In terms of plastic injection molding for automotive areas, deciding on the correct provider is vital for the success of your respective project. The automotive industry demands exceptional precision, longevity, and effectiveness, generating provider choice additional than just a transaction but a long-expression determination to good quality and trustworthiness. no matter whether your concentration is production vital automotive parts or incorporating impressive types into output, picking out the appropriate provider decides the products's general performance and compliance with industry specifications. Here's an in-depth take a look at what you must prioritize when dealing with automotive injection molding professionals.

Table of contents:

assessing provider know-how and producing abilities

evaluating top quality Management steps and Certifications

comprehending Lead occasions and generation versatility

creating very long-time period Partnerships with reputable Suppliers

assessing provider Expertise and producing Capabilities

step one in picking out the right spouse for automotive injection molding is To judge their complex abilities and production abilities. Suppliers Geared up with Highly developed injection molding machines, such as All those described on Carvo’s Internet site, demonstrate a chance to produce specific factors regularly. Key variables to assess include things like if the provider focuses on plastic injection molding automotive pieces, the complexity of factors they can develop, and their familiarity with sector-distinct specifications. try to find signs of adaptability, including a chance to make parts with superior sturdiness and humidity or heat resistance. an excellent supplier will never only satisfy expectations but exceed them with innovative approaches and technologies personalized to further improve longevity and overall performance in automotive purposes.

examining top quality Handle actions and Certifications

top quality need to be the spine of any supplier partnership, specially when managing automotive pieces producing. start out by ensuring that your prospective supplier follows rigid market criteria like ISO 9001 or IATF 16949 for quality management methods. These certifications indicate a business’s dedication to providing continually higher-excellent products. Moreover, inquire regarding their high-quality control steps, from Uncooked material collection to inspections carried out for the duration of and once the output system. By way of example, Carvo emphasizes arduous Procedure and maintenance of its injection molding devices to be sure goods satisfy stringent specifications. strong good quality assurance procedures don't just promise reliability but in addition safeguard you from highly-priced defects and reputational hurt down the road.

being familiar with Lead periods and output adaptability

well timed delivery of automotive pieces is very important to ensuring clean functions, notably in quickly-paced producing timelines. A reliable provider should have the output overall flexibility needed to accommodate your job’s certain requires and adjust to fluctuations if you want volumes without the need of compromising top quality. Seek apparent interaction about direct instances and the supplier’s ability to take care of creation efficiently throughout peak and off-peak seasons. Suppliers employing Sophisticated plastic injection molding machinery, like Carvo, usually have an edge in streamlining the production procedure, guaranteeing that orders are both of those accurate and punctual. deciding upon a supplier with these types of abilities minimizes threats related to delays and aids in greater task scheduling.

making prolonged-time period Partnerships with dependable Suppliers

When deciding upon a provider for automotive injection molding, it’s important to Assume past just one transactions. a powerful, long-time period partnership which has a reliable provider offers a number of benefits, from cost-performance to assured use of the most up-to-date innovations. Evaluate a supplier’s reputation in customer care, innovation, and trouble-fixing. Do they prioritize constant advancement and invest in Sophisticated technologies like higher-precision molding? Are they open up to collaborating on custom made solutions tailor-made in your particular requires? trusted suppliers, like Carvo, excel in building lasting interactions by giving multipurpose, customizable selections that evolve with their customers’ expansion. take into account variables like eco-friendly tactics, scalability, and an Total determination to excellence to ensure you’ll Possess a dependable companion For some time to return.

picking out the suitable injection molding associate for automotive pieces is important for guaranteeing high quality, trustworthiness, and innovation within your creation procedures. By cautiously vetting suppliers for knowledge, good quality measures, manufacturing performance, and extended-time period compatibility, your organization gains not simply a production lover but a competitive edge during the demanding automotive sector. All things considered, the appropriate provider doesn’t just produce parts; they supply trust and excellence. website

Rick Moranis Then & Now!

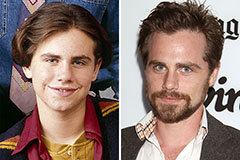

Rick Moranis Then & Now! Rider Strong Then & Now!

Rider Strong Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now!